IFR FaD 3 – the LWR versus IFR fuel cycle

16 February 2010 on BraveNewClimate.com

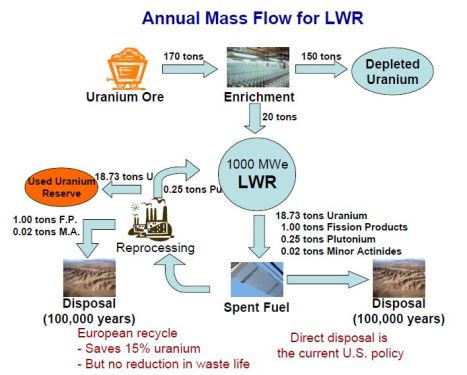

The following post in the Integral Fast Reactor Facts and Discussion series centres around two important diagrams prepared by Dr Yoon I. Chang – Distinguished Fellow at Argonne National Laboratories, a key figure in the development of the IFR between 1984 and 1994, and founding member of the Science Council for Global Initiatives. These allow one to easily — visually — see the difference between the uranium fuel cycle of today’s Gen II and Gen III light water reactors, and the alternative mass flow represented by the IFR.

In the previous IFR FaD post, I discussed the amount of uranium fuel an IFR consumes (i.e., 1 tonne of natural or depleted uranium per gigawatt year, which is roughly 160 times more efficient in its use of uranium than a Generation III light water reactor). For another technical explanation, see here.

First, let’s consider the uranium fuel cycle in today Nuclear Light Water Reactors, with or without aqueous plutonium recycle:

To run a 1 GWe reactor for 1 year, about 170 tons of uranium ore is required. After enrichment of U-235 to 3.5 – 5%, this yields about 20 tonnes of material suitable for manufacture into uranium oxide fuel pellets (at ~50,000 MWd/t burnup). The rest is discarded as ‘depleted uranium’, which still contains about 0.25% U-235. After a year of operation, the following ‘waste’ results: 18.73 t of uranium (mostly U-238), 1 t of fission products (the atomic shards left over after heavy fissile isotopes are split), 0.25 t of plutonium (i.e., 250 kg, which has been bred in the reactor as a result of U-238 absorbing a neutron and then undergoing a couple of beta decays) and 0.02 t of minor actinides (mostly americium and curium).

This ’spent fuel’ can be either secured for eventual storage in a deep geological respository (hint: bad idea), or reprocessed to recover the Pu for further fissioning. The result of this type of reprocessing, adopted by the French, is that instead of getting six-tenths of 1 per cent of the energy out of mined uranium, we get eight-tenths, with no significant reduction in waste life. Only one or two passes are possible. Wow… excuse me if I’m not particularly impressed (it’s also an expensive process and rings proliferation alarm bells for some folks).

Now, let’s consider the alternative IFR fuel cycle:

First, note that no mining is required — this will be true for many centuries, until all of the existing used fuel (left over from LWRs) and depleted uranium that we have stockpiled is consumed, to make a lot of electricity.

First, 700 tons of LWR spent fuel must be reprocessed to extract ~10 tonnes of fissile actinides (mostly Pu, Am and Cm of various isotopes, and laced with some trace lanthanoids which keeps it ‘hot’). More detail on this ‘fissile load’ will be given in future posts. This one-time reprocessing also results in 80 t of makeup uranium (40 t for the core, such that the resultant metal fuel rods are ~20 % fissile, and 40 t for the breeder blanket), with the remaining uranium being available for future inputs as this plant, and others, generates electricity, year in, year out. About 1.5 t per GW year will be needed if the IFR is running at a high fissile-fuel-breeding rate. Note: The blanket uranium loading will be zero for a burner configuration, and much larger amounts for maximum breeding. The amount used in the diagram is something in between.

Each year, an average of 13.5 t of nuclear fuel will be removed from the reactor and run through the on-site pyroprocessing unit (details in later posts). This procedure allows separation of the fission products from the heavy metals (which are recycled back into the IFR). The F.P. are encased in a highly durable, inert glass (or perhaps a synroc), and must be isolated for 300 to 500 years to allow for 10+ half-lives of Sr-90 and Cs-137. No long-term (multi-millennial) geological disposal is required.

As a high priority, Tom Blees, Yoon Chang and others are now working towards getting the first LWR spent fuel recycling plant built in the US. Tom discussed this initiative during his recent seminar at ANSTO. The prospects are looking bright.

And what of the ‘excess actinides for startup of new IFR‘? This is a very important point, and will be the topic of the next IFR FaD post. This, in turn, will lead naturally into an exploration of the feasible fuel breeding and roll out rates for IFR power plant deployment over the coming decades.